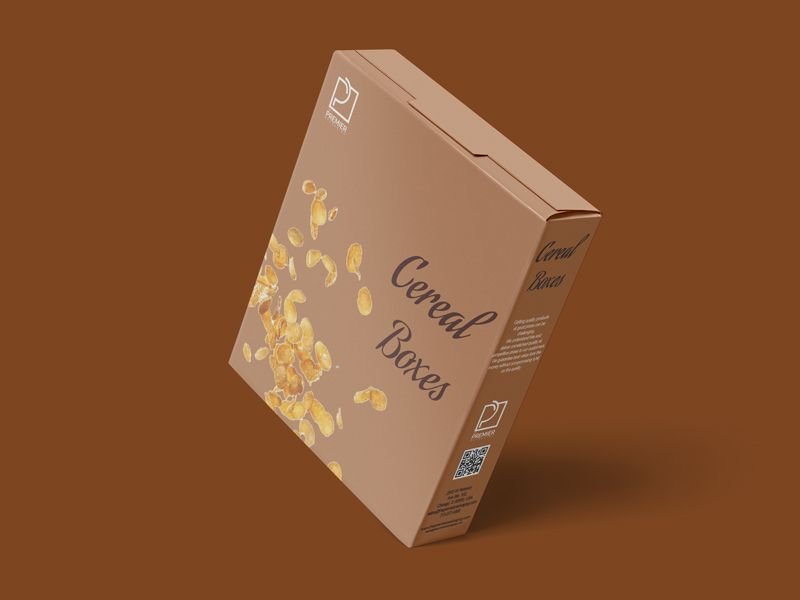

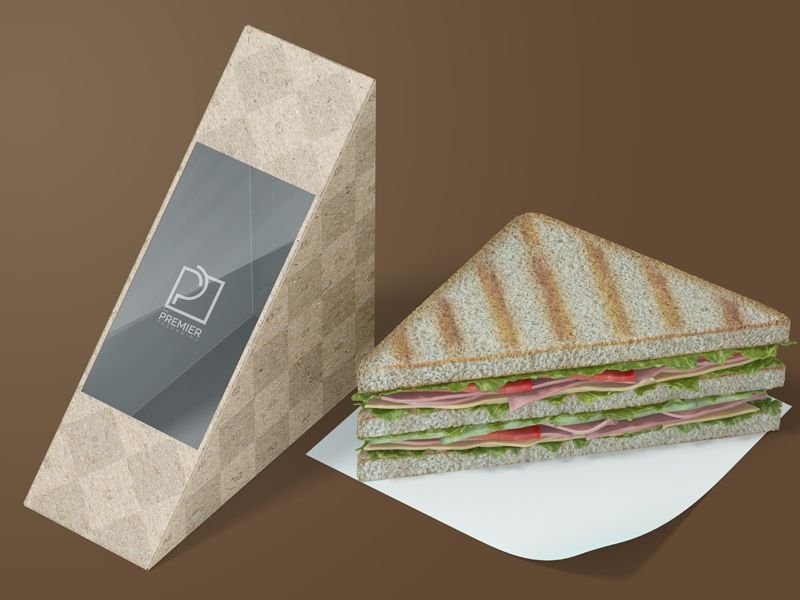

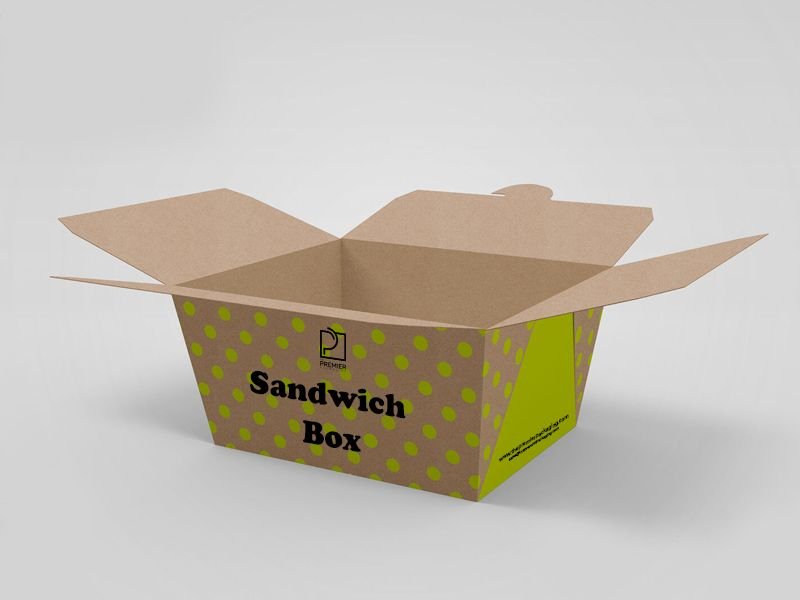

Sandwich Boxes

Designed for convenience and style, these cardboard sandwich boxes with lids are perfect for takeaway services. Tailor them to your brand's needs, ensuring your sandwiches are presented impressively and preserved effectively. Our boxes are not just practical; they are an extension of your brand identity, offering an unmatched combination of durability, aesthetics, and functionality in the competitive food market.

Read More...£0.50/unit

Price as low as

instock

Warranty

Estimated arrival:

Standard: 14 to 16 Business Days

Express: 10 to 12 Business Days

Expedite: 8 to 10 Business Days

Need more this year? Get The Most Accurate Quotation

| Specifications | |

|---|---|

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock |

|

| Quantities | 100 – 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options |

|

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 4-6 Business Days, Rush |

- FAQ

- Description

Custom Sandwich Boxes: Combining Functionality with Style

Our Custom Sandwich Boxes are crafted to provide an optimal packaging solution for sandwich shops and eateries, blending practicality with aesthetic appeal.Tailored Designs for Your Brand's Unique Needs

We offer a broad range of customization options for our sandwich boxes, ensuring they perfectly align with your brand's image and customer expectations. Whether you're looking for classic, minimalist designs or bold, eye-catching styles, our team is dedicated to creating packaging that not only protects your sandwiches but also enhances their shelf presence and brand recognition.Innovative and Eye-Catching Box Designs

Using the latest design techniques, our team creates sandwich boxes that are visually appealing and functionally superior. We focus on designs that protect the sandwiches, ease the takeaway experience, and make your brand memorable in the competitive food industry.Quality and Sustainability: Core Values in Sandwich Box Production

Our commitment to quality and environmental responsibility is central to our choice of materials and manufacturing processes for sandwich boxes.Premium Cardboard Materials for Durability and Presentation

We use high-quality cardboard materials in our sandwich boxes, ensuring they are durable, attractive, and capable of maintaining their aesthetic appeal. Our boxes are designed to protect the sandwiches while providing an appealing packaging solution that resonates with eco-conscious consumers.Sustainable Packaging for a Healthier Planet

Our eco-friendly approach to packaging extends to our sandwich boxes, meeting the increasing demand for environmentally responsible products. This commitment ensures our packaging solutions are effective and contribute to a more sustainable future.Versatility in Sandwich Box Options

Our range of Sandwich Boxes is designed to cater to a variety of packaging needs, offering versatile options for businesses of all sizes in the food sector.Adaptable Packaging for Various Sandwich Types

Whether you’re packaging classic sandwiches, wraps, or specialty creations, our boxes are designed to accommodate different types and sizes of sandwiches securely and attractively. We ensure each box is perfectly suited to your specific products, offering both protection and an appealing presentation.Personalization for Enhanced Brand Recognition

We offer extensive customization options, including unique designs, printing, and sizes, to make each sandwich box a reflection of your brand's identity. This level of personalization is ideal for building a strong brand presence and enhancing customer loyalty.Ensuring Quality and Satisfaction in Every Sandwich Box

Our commitment to excellence ensures that each sandwich box meets the highest standards of quality and design, enhancing the overall customer experience.High Standards for Reliable Packaging

We rigorously test our sandwich boxes to ensure they meet stringent quality and safety standards. This commitment guarantees that every box not only protects its contents but also adds value to the customer experience with your brand.Prioritizing Safety and Aesthetics in Packaging Design

Quality and safety are paramount in our packaging design, especially for food products like sandwiches. We incorporate features that ensure the safety and integrity of the food, offering peace of mind and satisfaction to both businesses and consumers.Conclusion: Your Trusted Partner in Sandwich Packaging

Choosing The Premier Packaging for your sandwich boxes means partnering with a leader in innovative, eco-friendly, and customer-focused packaging solutions. Our dedication to quality, customization, and customer satisfaction ensures your sandwiches are not just packaged, but presented in a way that elevates your brand and captivates your customers.Frequently Asked Questions

A: Yes, The Premier Packaging specializes in creating custom boxes tailored to your brand and product specifications.

A: Our production and delivery times may vary depending on the complexity of your order, but we strive to provide fast and efficient service. Contact our team for more details.

A: A: Absolutely! We understand the importance of sustainability. The Premier Packaging offers a range of eco-friendly packaging solutions. Just let us know your preferences, and we’ll find the right fit for you.

A: Yes, we offer warehousing solutions for your packaging needs. This allows you to order in larger quantities and manage storage more efficiently.

A: We cater to a wide range of industries, including food and beverages, cosmetics, electronics, and more. Our solutions are versatile and adaptable to various businesses.

A: You can easily reach out to us through our contact page, where you’ll find various ways to connect with our knowledgeable team. We’re here to assist you with any questions or requests you may have.

Sandwich Boxes

Designed for convenience and style, these cardboard sandwich boxes with lids are perfect for takeaway services. Tailor them to your brand's needs, ensuring your sandwiches are presented impressively and preserved effectively. Our boxes are not just practical; they are an extension of your brand identity, offering an unmatched combination of durability, aesthetics, and functionality in the competitive food market.

Read More...£0.50/unit

Price as low as

instock

Warranty

Estimated arrival:

Standard: 14 to 16 Business Days

Express: 10 to 12 Business Days

Expedite: 8 to 10 Business Days

- Coating Laminations

- Printing Options

- Materials

- Special Finishes

- Paper Weight

Aqueous Coating

Clear, fast-drying, water-based, and eco-friendly coating. Available in gloss or matte finish.

UV Coating

Fast-drying coating cured with ultraviolet light. Available in gloss or matte finish.

Soft Touch Coating

UV coating that is applied to a specified area and cured using ultraviolet light.

Soft Touch Coating

Soft to the touch coating that creates a velvety texture for a more tactile appeal.

Varnish

Clear coating applied using the CMYK printing method. Available in gloss, satin, or matte.

Lamination

Laminated protective film that adheres to the surface of packaging materials to maximize durability.

Anti-scratch Lamination

Laminated BOPP film that is scratch, scuff, and fingerprint resistant. Cost-effective option.

Soft Touch / Silk Lamination

Soft to the touch lamination similar to peach skin. Available in a satin or matte finish.

Offset Print

High-quality printing method that utilizes a printing plate and rubber blanket to transfer designs on paper. Best for large runs.

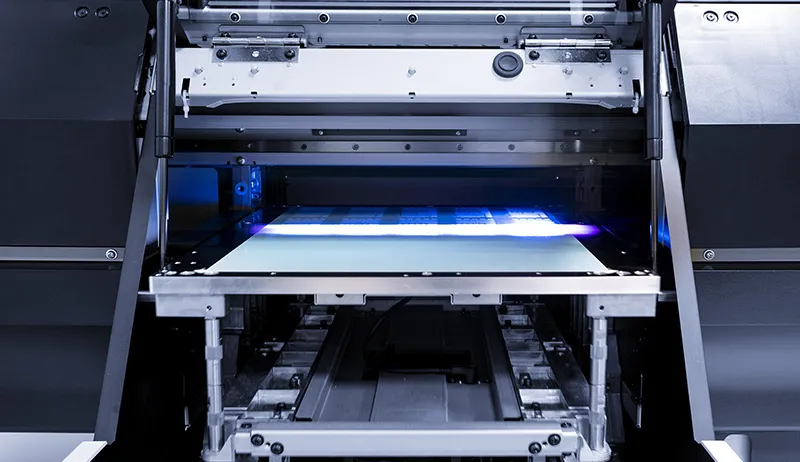

Digital Print

Digital printing method that requires no printing plate. Designs are transferred electronically, making it cost-effective for small runs.

UV Print

Fast-drying printing method using ultraviolet lights to cure inks which results in a gloss finish.

Water-based Ink

Comprised of water and pigment that provides high-quality color output and is 100% eco friendly.

Soy / Vegetable Ink

100% eco friendly and comprised of soy/vegetable oil and pigment to provide a vibrant color output.

Oil Base Ink

Non-eco-friendly ink comprised of oil and pigment that provides high-quality color output.

Pantone

Pure color based on specific ink formulas to consistenly and precisely print color.

Pantone Metallic

Metallic color based on specific ink formulas to consistenly and precisely print color.

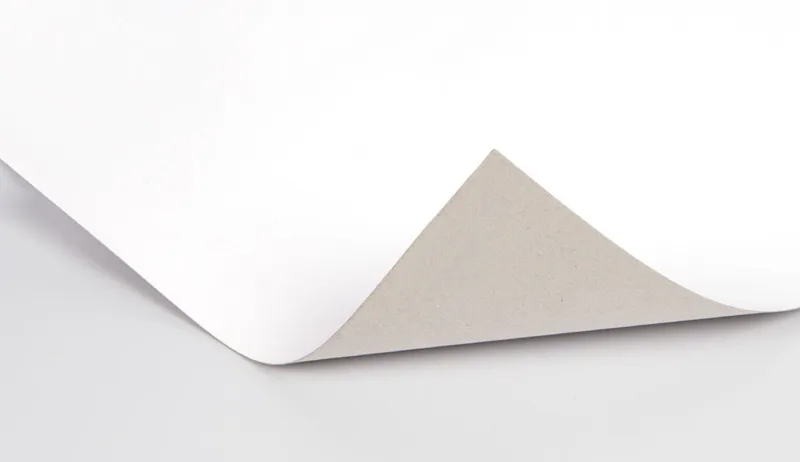

SBS C1S

Premium-grade bleached white paperboard coated on one side for high-quality printing and finishes.

SBS C2S

Premium-grade bleached white paperboard coated on two sides for high-quality printing and finishes.

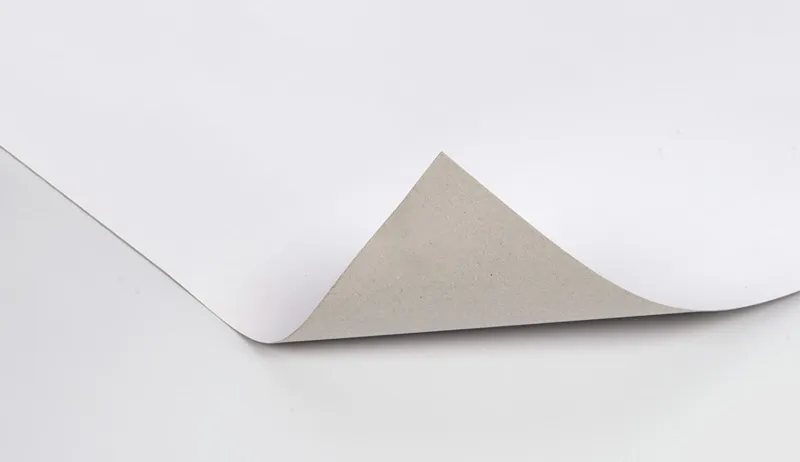

CCNB

Duplex paperboard made from 90% recycled paper pulp with a white surface for high-quality printing.

Fully Recycled CCNB

Duplex paperboard coated on one side and made from 90% recycled paper pulp.

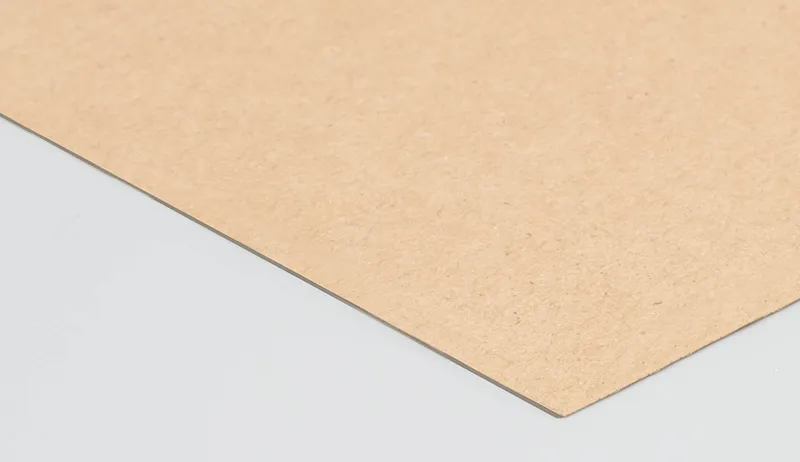

Natural Brown Kraft

Kraft paper made from a mix of virgin and recycled paper pulp, coated on both sides for printing.

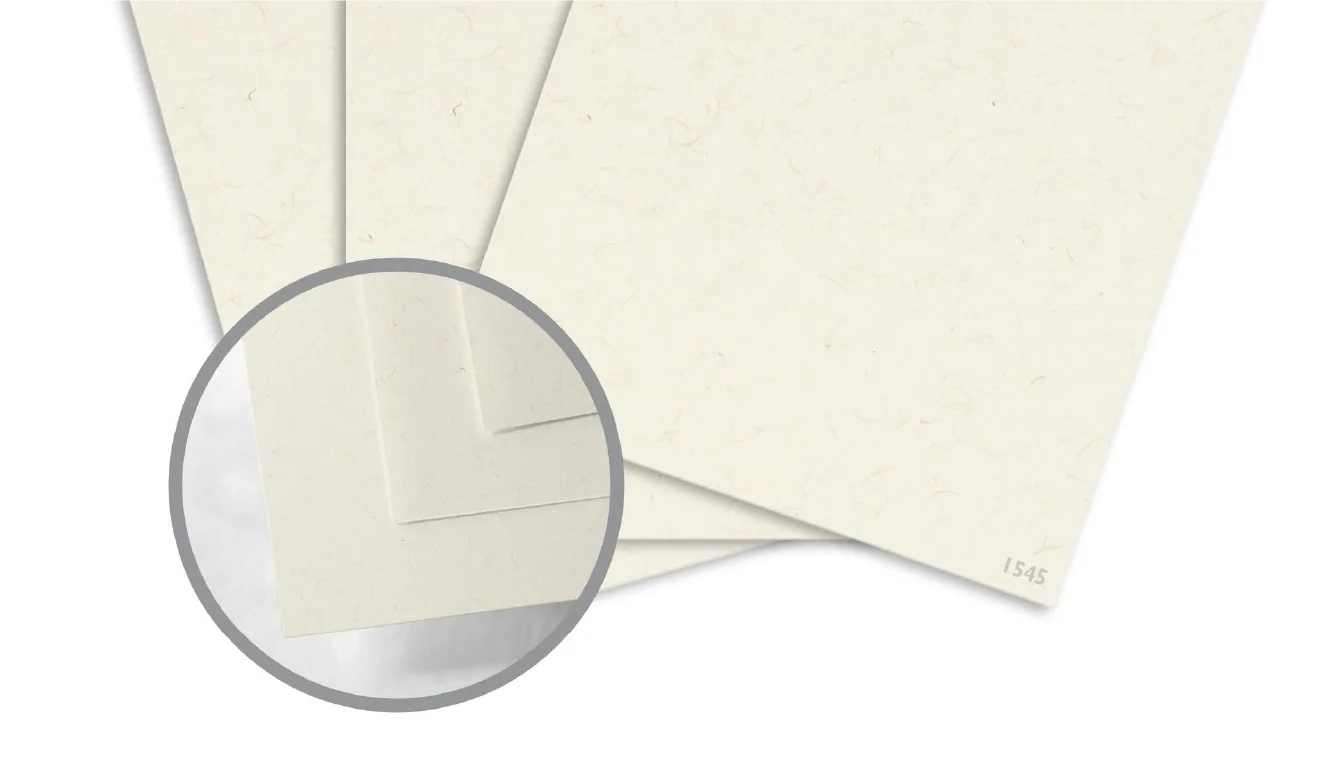

White Kraft

Bleached kraft paper made from a mix of virgin and recycled pulp with coating on both sides for printing.

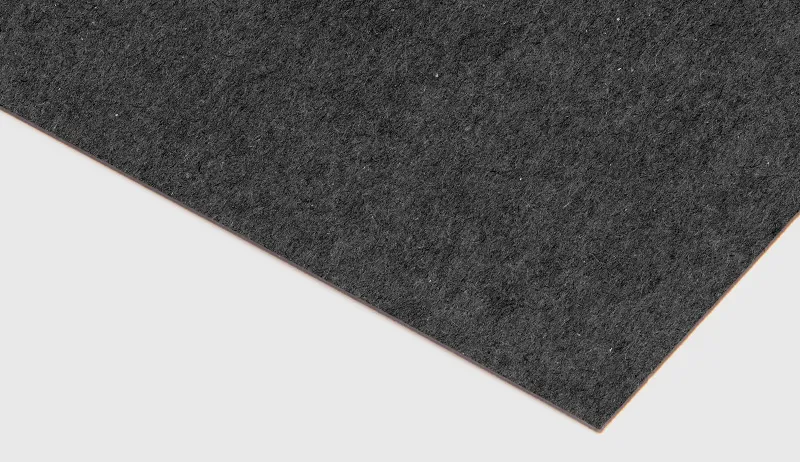

Black Kraft

Black dyed kraft paper made from a mix of virgin and recycled pulp, coated on both sides for printing.

Uncoated Unbleached Kraft

Unbleached kraft paper with no coating. Made from a mixture of virgin and recycled paper pulp.

Hot Foil Stamping

Form of relief printing in which foil is transferred to a surface at high temperatures.

Cold Foil Printing

Form of relief printing in which foil is transferred to a surface by pressing onto UV curable adhesives.

Blind Embossing

Form of relief printing in which dies is pressed on the back of the material to form a raised motif.

Blind Debossing

Form of relief printing in which dies is pressed on the front of the material to form a raised motif.

Registered Embossing

Form of relief printing in which a die is pressed on the back of the material to form a raised motif.

Combination Embossing

Combination between embossing and foil stamping. It creates a 3D motif that features a foil finish.

Window Patching

Die-cut shape is layered with plastic film to feature a window showcasing the product inside.

GSM

Measurement for the density of the paper stock.

PT

Measurement for the thickness of the paper stock.

Flute

Fiberboard arches sandwiched between two linerboards.